How to Choose the Best Miter Saw Blade

When you want to make the most out from your miter saw, one aspect that you should look into is the circular blade that you are using. The quality of your output or the cuts that you are making solely depends on this blade. Thus, you need to know what is the best blade to use according to what result you would want to achieve.

Choosing the right kind of blade has a lot of good effects, not just to the outcome of your work but even to your miter saw. To name a few, here are what these good quality blades can do:

- A good quality of blade will practically make an effective cut on the wood or any substance you are cutting. Thus, this will make the cutting time faster and the cut surface look smother and cleaner.

- A blade that can smoothly run or slide unto the surface of the substance being cut will definitely save your miter saw’s motor from early damage. If the motor is putting out so much heat energy to forcibly run the blade through the substance that you are cutting, then it will be more bound to being worn out.

- Safety is always a big factor. Keeping a good working blade should be done for the purpose of ensuring safety all throughout your operations on your miter saw.

The Best Characteristics

There are a lot of ways and different points of view from miter saw experts on what makes up a best circular blade. But for now, we are going to let you know of just four basic characteristics that you can look into when choosing your miter saw blade.

Tooth Count

There different expert opinion about which number of teeth is optimal for use. Some say it should be at least 60 as this will provide a nice smooth cut to your substance while others disagree on this.

Despite this varying opinion, the best tooth count for a saw blade actually depends on the type of cut that you are making and the substance that you are cutting. Thus, it will all depend on the user’s preference as there is really no definite number of teeth that makes up a good quality blade. Here is your guide:

A. Around 24 teeth which is called as a ripping blade

When to Use: 24-toothed blade is best to be used when doing a rip cutting on a natural wood

Reason: With lesser tooth count, there will be a large area in the gullet, which is the area between the teeth. The bigger the area in between teeth, the more capable the blade is in moving further to cut bigger volumes of wood.

B. At least 60 teeth and preferably 80 which is called as a cross cutting blade

When to Use: 60 to 80 toothed blades is best to be used when doing a cross cutting on a natural wood. However, this is also more preferable in doing both cross cutting and rip cutting for those man-made materials such as plywood, Medium-density fiberboard (MDF), chip boards and non-porous materials like aluminum. Man-made materials most likely don’t have definite grain structure.

Reason: The greater the tooth count, the finer the cut it can do. However, this is more preferred in making shorter cuts because of the smaller area in the blade gullet.

C. From 40-50 which is called as a combination blade

When to Use: A combination blade, from the name itself, can actually do both rip cutting and cross cutting at the same time. Although it is not the best for both cuts, this kind of blade can do better if you do not want to change blade more often.

Reason: Its number of tooth simply makes the average of both preceding types that is why it can do both yet not to the extreme of being the finest for both cuts.

There are also instances when these blades have a graph labeled on it which will aid you as to which material and type of cut could that certain circular blade be more useful.

Hook Angle

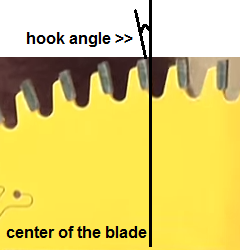

Hook angle refers to the angle between an edge of the tooth and the center of the blade. The hook angle of a blade is also commonly defined on the blade’s label. A good quality blade should have a hook angle from -5 to +7 degree. The more positive a blade’s hook angle is, the greater the tendency that it will become too grabby to the substance being cut.

Tooth Geometry

Tooth geometry refers to the way the blade’s tooth is being cut. There are around five kinds of tooth geometry defined in the industry of circular blade making but the outstanding one is the Triple Chip Grind (TCG).

Experts say that having a TCG tooth geometry is the best option as it gives a smooth cutting flow while it can do cutting on both on solid wood and other non-porous materials like aluminum and plastic.

Manufacturing Approach

Lastly, the manufacturing approach of a saw blade can also greatly affect the performance of your miter saw. There are two kinds of manufacturing approach of these blades.

A. Stamped Blade

Manufacturing Method: The metal is melted and molded into round then stamped out of the molder.

Manifestations: The blade rings when it is struck with a metal and you can feel a vibration when you touch the blade. This further means a higher resonance and may not result to a perfect cut. The expansion slot, which is intended for the blade not to warp, appears as a line with a hole in the end

This is best used for making a fence for your miter saw or pallets for fire wood. This is cannot give a good result when you want to do a fine wood work.

B. Laser cut blade

Manufacturing Method: Harder steel is being cut through laser to form the circular blade.

Manifestations: No resonance or ringing sound when the blade is struck with metal. The expansion slot appears like an upside down question mark with a very thin line and no holes on its edge.

This is best Used for making wood works where you want to achieve a finer cut. This is usually bought when users want to have their blades sharpened rather than buying a new one.

We hope that our guide will become helpful to you in making your choice of circular saw blade for your miter saw. Whether you follow our tips or not, the bottom line would always be in getting the most out of what you paid for.

Incoming search terms:

- miter saw blades

- best miter saw blade